Introduction

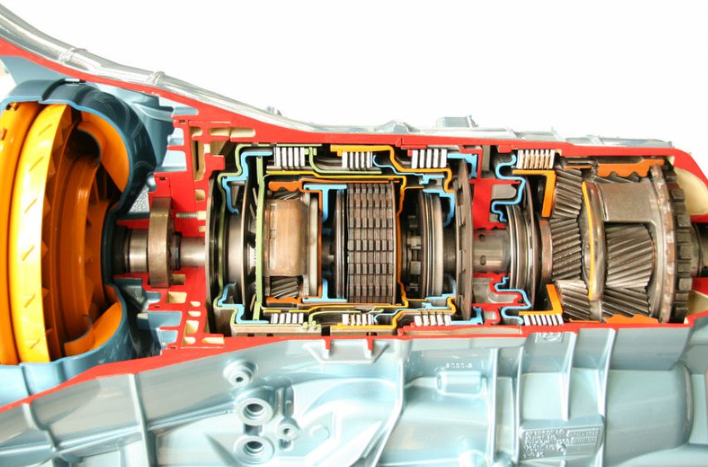

Automatic transmissions are among the most intricate systems in the modern automobile. Built on precision mechanics, hydraulics, and electronic control, they manage the power between the engine and the wheels while ensuring smooth performance. One of the most respected examples is the ZF 6HP generation 2 solenoid diagram, which represents the inner workings of a transmission used across several premium vehicles. By understanding this diagram, mechanics and drivers gain insights into the reliability, efficiency, and complexity of the ZF 6HP system.

Understanding the ZF 6HP Transmission

ZF Friedrichshafen AG, a German company renowned for engineering excellence, introduced the ZF 6HP. It marked a turning point in automatic transmission design by offering six forward gears, adaptive shift programs, and a compact structure that fit both rear-wheel and all-wheel drive vehicles. The inclusion of electronic solenoids, which controlled hydraulic fluid with precision, allowed smoother shifts and reduced fuel consumption.

This transmission became a benchmark in the early 2000s and was widely adopted by manufacturers such as BMW, Audi, Jaguar, and Land Rover. Its success rested not only on performance but also on durability, making it one of the most popular gearboxes in its class.

What Makes Generation 2 Different?

The second generation of the ZF 6HP introduced significant improvements over the original. While the first design was already groundbreaking, it faced challenges such as occasional shift harshness and solenoid wear. Generation 2 addressed these concerns with redesigned valve bodies, upgraded solenoids, and smarter transmission control software.

As a result, drivers experienced faster and smoother gear changes, greater fuel economy, and enhanced longevity of internal components. These updates gave the 6HP a second life in the competitive automotive market, ensuring that it remained relevant even as eight-speed models began to dominate newer vehicles.

The Role of Solenoids in Transmission

To fully understand the diagram, one must first grasp what solenoids do inside the transmission. A solenoid is an electromechanical valve that opens or closes depending on signals from the transmission control module. These signals regulate hydraulic pressure and direct it to specific clutch packs, which engage or release to shift gears.

Without solenoids, the transmission would not know when to shift, nor would it be able to execute the seamless gear transitions that modern drivers expect. Solenoids act as the messengers between the digital brain of the transmission and its hydraulic muscles.

Breaking Down the Solenoid Diagram

The zf 6hp generation 2 solenoid diagram illustrates how fluid passages, solenoids, and valves interact. Each solenoid has a defined position in the valve body and serves a specific function. Pressure control solenoids manage hydraulic pressure, shift solenoids direct fluid to clutch packs, and the torque converter clutch solenoid governs the engagement of the lock-up clutch.

The diagram is not simply a schematic; it is a visual roadmap of the transmission’s nervous system. It shows how electronic signals translate into hydraulic actions that move mechanical components. For technicians, the diagram is a vital diagnostic tool. For enthusiasts, it is a glimpse into the precision engineering behind every gear change.

How Solenoids Control Gear Shifts

When the vehicle is in motion, the transmission control module receives data from sensors such as throttle position, speed, and load. It then determines which gear is most efficient and sends an electrical pulse to the appropriate solenoids. As the solenoids open or close, hydraulic fluid flows into specific passages, applying or releasing pressure to clutch packs.

For example, during a shift from second to third gear, one solenoid gradually reduces pressure on the releasing clutch while another increases pressure on the engaging clutch. This balancing act ensures that the gear change feels smooth rather than abrupt. Without this precise timing, the transmission would suffer from slips, jerks, or harsh transitions.

Common Issues with Solenoids

Despite their sophistication, solenoids are not immune to wear. Over time, they may stick, burn out, or lose responsiveness. The most common symptoms of failing solenoids include delayed shifts, slipping gears, harsh engagement, or even the transmission refusing to shift at all. In many cases, the check engine light will illuminate, and fault codes stored in the control module will point to the affected solenoid.

The root causes vary. Contaminated fluid can clog passages, while electrical issues may disrupt communication between the control unit and the solenoids. Prolonged heat exposure is another factor that accelerates solenoid deterioration.

Diagnosing Solenoid Problems

Technicians rely on multiple methods to identify faulty solenoids. Diagnostic scanners read error codes that highlight malfunctioning circuits. Hydraulic pressure tests can confirm whether fluid flow is behaving as expected. In some cases, the solenoids are removed and inspected physically for signs of contamination, sticking, or electrical damage.

Understanding the solenoid diagram is particularly important at this stage. By following the schematic, a mechanic can trace fluid flow, pinpoint the faulty valve, and confirm whether the issue lies in the solenoid itself or in the surrounding valve body.

Repairing and Replacing Solenoids

Repair often depends on the extent of the damage. A single solenoid may be replaced without disturbing the entire system, but since they age together, many workshops recommend replacing all solenoids at once. This prevents future breakdowns and ensures consistent performance.

If multiple solenoids or passages are compromised, the better solution is a complete valve body overhaul. Though more expensive, it restores the entire hydraulic control system. Costs vary widely: individual solenoid replacement may range between two to four hundred dollars, while full valve body replacement can climb above a thousand. In cases where solenoid failure has caused secondary damage, a full transmission rebuild may be required.

Preventing Solenoid Failures

Preventive care is the best way to avoid costly repairs. Regular transmission fluid changes every 60,000 to 80,000 miles keep the system clean and reduce wear. Using the correct ZF Lifeguard 6 fluid is essential, as substitutes may compromise solenoid function. Avoiding aggressive driving, especially when the transmission is cold, also prolongs component life.

By following these maintenance steps, drivers can ensure that the solenoids remain responsive, the valve body stays healthy, and the transmission delivers reliable performance for many years.

Industry Significance of the ZF 6HP

The widespread use of the ZF 6HP shows its importance in automotive history. Premium carmakers adopted it not only for its efficiency but also for its ability to handle powerful engines while maintaining smoothness. Even after the introduction of newer eight-speed models, the 6HP remains in service worldwide, ensuring that technicians continue to study its diagrams and keep its components.

The Future of Transmission Technology

As vehicles evolve toward hybrids and electric drivetrains, the role of transmissions is changing. Fully electric cars may not need complex gearboxes, but hybrids still rely on them to balance combustion and electric power. Future solenoids may come with integrated sensors that monitor their own performance and send data directly to control modules. The lessons from the 6HP generation 2 system will undoubtedly influence these advancements.

Conclusion

The zf 6hp generation 2 solenoid diagram is more than a technical drawing; it is a key to understanding one of the most successful transmissions of its time. By studying how solenoids direct fluid flow and manage gear shifts, both mechanics and enthusiasts gain insight into the delicate balance of electronics, hydraulics, and mechanics.

Regular maintenance, timely diagnostics, and an appreciation of this system’s complexity ensure that vehicles equipped with the ZF 6HP continue to perform reliably. Though newer technologies are emerging, the influence of the 6HP generation 2 remains a cornerstone in automotive engineering.

FAQs

What does the solenoid diagram represent?

It shows how solenoids and fluid passages interact inside the transmission valve body.

How many solenoids are in the ZF 6HP Gen 2?

Most versions contain seven or eight solenoids, depending on the vehicle model.

Can faulty solenoids be repaired?

Minor sticking can sometimes be fixed, but in most cases, replacement is the safer choice.

How often should the transmission fluid be changed?

ZF recommends fluid changes every 60,000 to 80,000 miles.

Is the ZF 6HP still relevant today?

Yes, it remains widely used in vehicles across the globe, making knowledge of its diagram vital.